As an Amazon Associate, Modded gets commissions for purchases made through links in this post.

Curious about what’s happening under your car’s hood? Whether you’re a car enthusiast or just looking to save money on maintenance, understanding how to replace a timing belt is valuable.

What Does a Timing Belt Do?

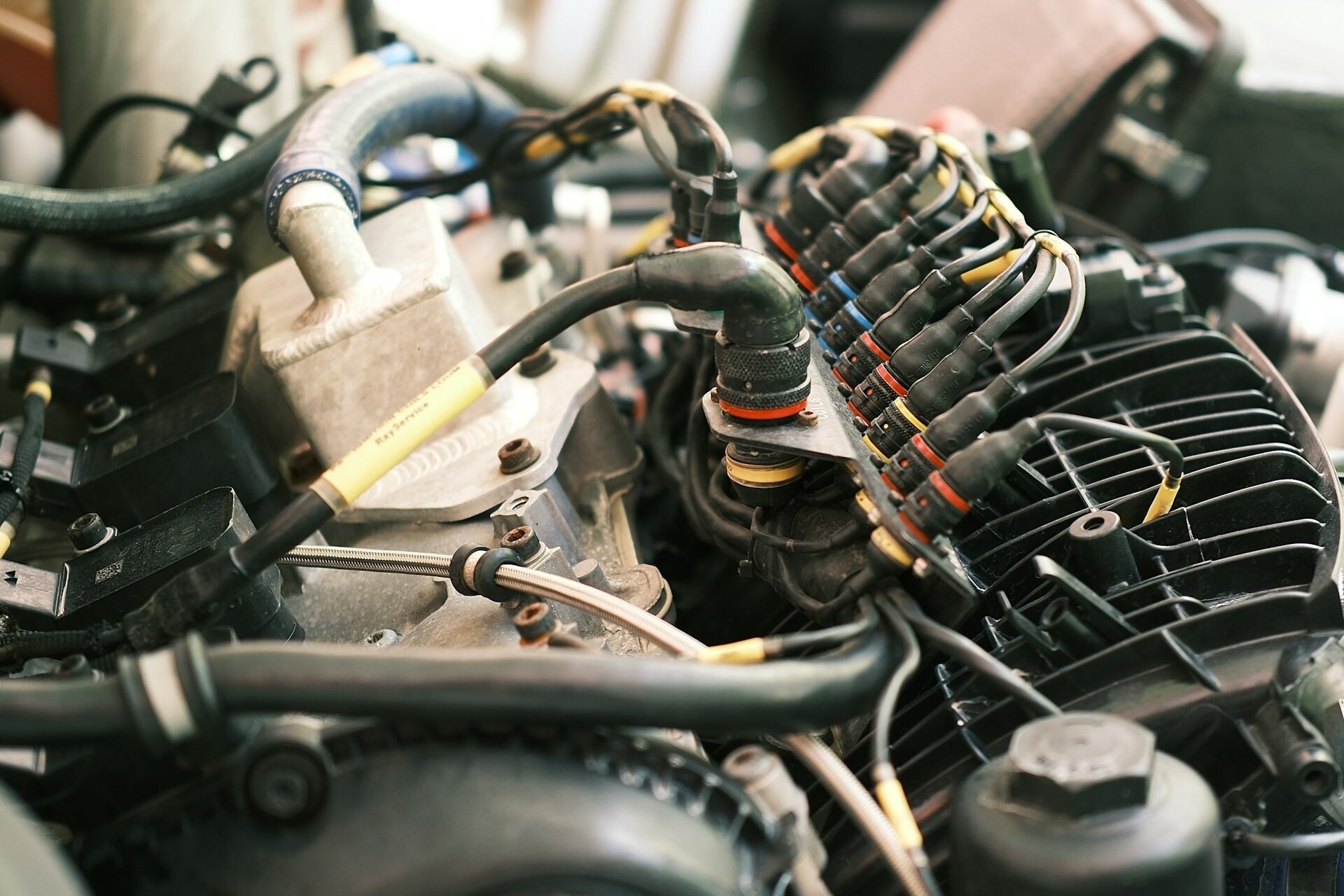

The timing belt is vital for the operation and performance of your vehicle’s engine. As a type of drive belt, its primary function is to synchronize the crankshaft and camshaft rotation. This synchronization ensures the engine’s valves open and close precisely during each cylinder’s intake and exhaust strokes.

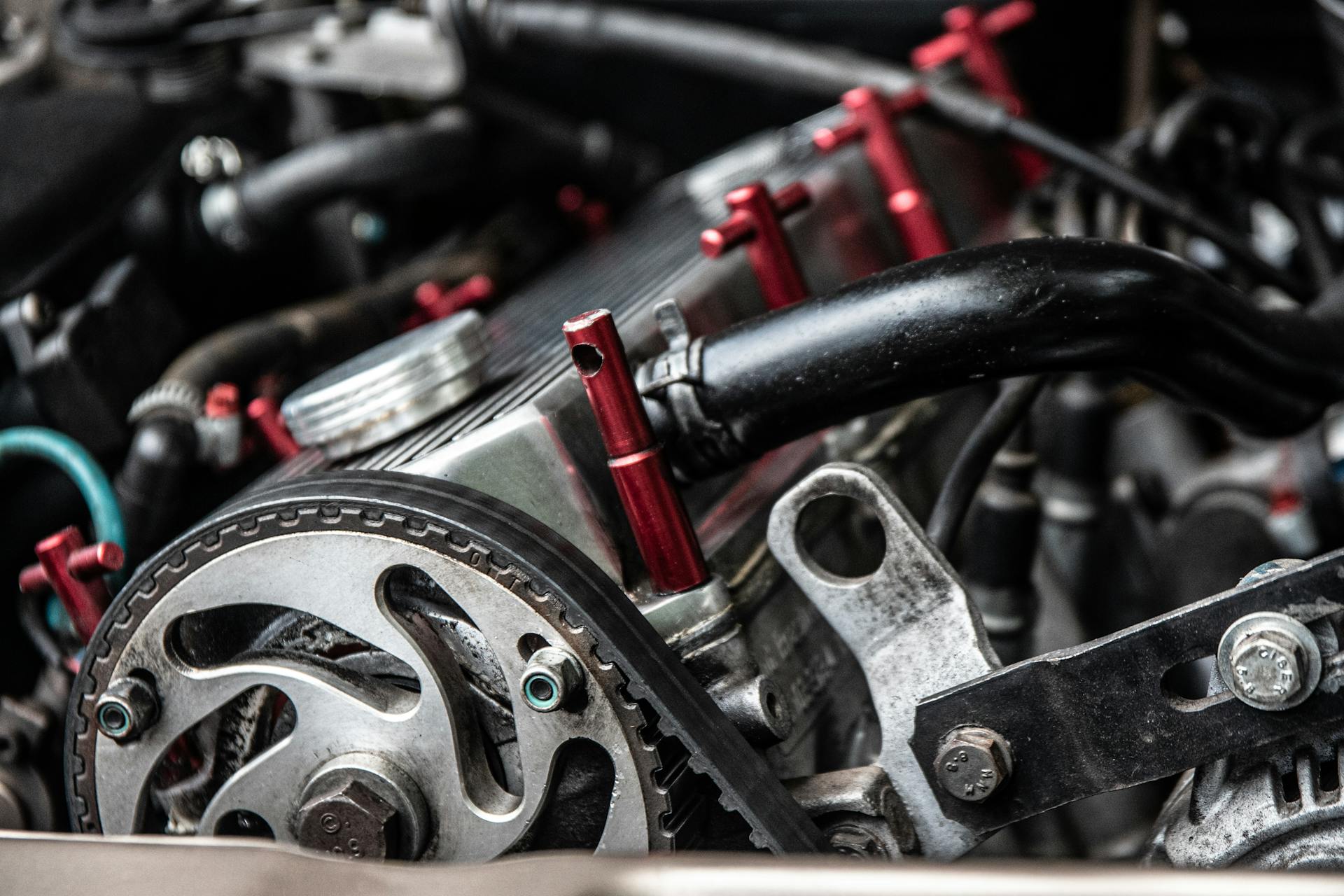

In a four-stroke engine, the crankshaft and camshaft must perfectly sync. The crankshaft — connected to the pistons — moves up and down. The camshaft operates the valves and must rotate at exactly half the speed of the crankshaft. This precise timing allows the valves to open and close at the right moments, letting air and fuel into the combustion chamber and exhaust gases out.

The timing belt achieves this synchronization through a series of teeth on its inner surface that mesh with sprockets on the crankshaft and camshaft. As the crankshaft rotates, it turns the timing belt, which in turn rotates the camshaft. The teeth’s design and placement ensure this rotation happens at the correct ratio, maintaining the essential timing between these two components.

In many engines — particularly interference engines — the timing belt also prevents the pistons from colliding with the valves. If the timing belt were to break or slip in these engines, the pistons could strike the valves, causing severe and often irreparable damage.

Drive Belt vs. Timing Belt

Drive belts are essential components in your vehicle’s engine. They transfer power from the engine’s crankshaft to other parts and accessories.

While some assume the timing and drive belts are interchangeable, that’s not the case. Timing belts are a kind of drive belt, but not the only one in your engine.

While the timing belt operates inside the engine to synchronize its internal components, other drive belts typically run outside. These external drive belts power auxiliary systems such as the alternator, power steering pump, air conditioning compressor and sometimes the water pump.

Unlike the timing belt — which has teeth to maintain precise synchronization — these other drive belts often rely on tension and friction to transfer power. Additionally, a broken accessory drive can’t cause nearly as much damage as a broken timing belt, as it only leaves you without air conditioning or power steering.

Serpentine Belt vs. Timing Belt

The serpentine belt is another drive belt type that’s sometimes confused with the timing belt. Also known as an accessory belt, it is a single, long belt that drives multiple peripheral devices in the engine.

Named for its snake-like path around various pulleys, this component typically powers the alternator, power steering pump, air conditioning compressor and sometimes the water pump. It’s designed with a series of grooves or ribs running along its length, which help it maintain a firm grip on the pulleys it drives.

When you open the hood, the serpentine belt is visible on the front of the engine. The timing belt is hidden inside the engine behind a protective cover.

A failed serpentine belt will cause loss of power to accessories but not cause engine damage. They’re also last longer than timing belts and are easier and less expensive to replace.

Timing Belt vs. Timing Chain

While many vehicles use a timing belt, some employ a timing chain. A timing chain serves the same primary function as a timing belt — synchronizing the crankshaft and camshaft(s) rotation.

The primary differences between timing belts and timing chains are:

- Material: Timing belts are made of reinforced rubber, while timing chains are metal, typically resembling a bicycle chain.

- Durability: Timing chains generally last longer than timing belts, often lasting the engine’s lifetime.

- Noise: Timing chains are usually noisier than belts, especially as they wear.

- Maintenance: Timing belts require regular replacement, while timing chains may need occasional adjustments but rarely need replacement.

- Cost: While timing chains are more expensive to replace if they wear out, the less frequent need for replacement can make them more economical in the long run.

- Weight: Timing belts are lighter, which can contribute to slightly better fuel efficiency.

- Applications: Due to their strength, timing chains are better suited for high-performance applications.

How to Tell if the Timing Chain is Bad

While timing chains are generally more durable than belts, they can still wear out over time. Here are some signs your timing chain might be falling:

- Engineer misfires: A stretched timing chain can cause the engine timing to be off, leading to misfires or rough running.

- Metal shavings in oil: As the chain wears, it can leave small metal particles in the engine oil.

- Rattling noise: A characteristic rattling or whirring noise can indicate a loose timing chain, especially when starting the engine or while it’s idling.

- The check engine light: Paying attention to the dashboard lights and learning what they mean is crucial. For example, the check engine light can tell you when there’s an issue with one or more engine components. A stretched or worn timing chain can trigger the check engine light.

- Engine performance issues: You might notice a lack of power at higher revolutions per minute or a decreased fuel efficiency.

If you suspect your timing chain is failing, have it checked by a professional mechanic promptly. Ignoring these symptoms can lead to much more expensive problems. Replacing a timing chain follows the same process as replacing a timing belt.

Symptoms of a Bad Timing Belt

Recognizing the signs of a failing timing belt is essential for preventing severe engine damage. While timing belts are designed to last thousands of miles, they wear out over time. Knowing the symptoms can help you address potential issues before they lead to disastrous failure. Bad timing belt symptoms include the following.

Engine Issues

A worn timing belt can slip on the pulleys, causing the engine’s timing to be off and resulting in misfires. If you feel the engine stumble or hesitate, it may signify a bad timing belt.

A stretched or worn belt can cause a noticeable loss of engine power, particularly during acceleration or at higher speeds. In the worst-case scenario, if the timing belt has broken, the engine won’t be able to turn over or start. You might hear the starter motor engaging, but the engine won’t crank.

Timing Belt Noise

Different types of noise can indicate various issues. These include:

- Ticking or clicking: A rhythmic ticking or clicking noise often indicates a loose timing belt or worn belt teeth.

- Slapping: A slapping noise might mean the timing belt is loose and slapping against the timing cover or other engine components.

- Squeaking: A high-pitched squealing noise — particularly during startup or when accelerating — might mean the timing belt is slipping.

- Rumbling: A low rumbling noise might indicate the timing belt tensioner is failing, causing the belt to become loose intermittently.

These noises can be intermittent and may be confused with other engine sounds. If you’re unsure, it’s best to have a professional mechanic diagnose the issue.

Decrease in Oil Pressure

If the timing belt has stretched or skipped a tooth, it can affect the camshaft’s operation. An incorrectly functioning camshaft can lead to a drop in oil pressure, as the pump may not be driven correctly. If you notice a decrease in oil pressure, it may signify a malfunctioning or old timing belt.

A drop in oil pressure can also affect the camshaft sensor due to excessive heat generation. If you notice a failing camshaft sensor, do not drive — it may fail to indicate a bad timing belt or another pressing issue.

Exhaust Issues

Unusual exhaust smoke or excessive emissions can sometimes be traced back to timing belt problems affecting the engine valve’s timing.

Preparing for Timing Belt Replacement

Replacing a timing belt is a complex job that requires careful preparation. Before you begin, it’s essential to gather all necessary tools and materials, ensure a safe working environment, and allocate sufficient time for the task.

Necessary Tools and Materials

To replace a timing belt, you’ll need:

- A socket set and ratchet

- A torque wrench

- A timing belt tensioner tool specific to your vehicle model

- A crankshaft pulley holding tool

- A jack and jack stands

- A new timing belt

- New tensioner and idler pulleys

- A new water pump — optional

- New camshaft and crankshaft seals, if necessary

- Engine cleaner and rags

- A flashlight or work light

- Safety glasses and gloves

Always consult your vehicle’s service manual for any model-specific tools or procedures. You can also purchase a timing belt kit, which provides everything for the replacement.

Timing Belt Replacement Cost

How much you’ll spend to replace a timing belt can vary significantly depending on your vehicle’s make and model and whether you choose to do it yourself or have it done professionally.

For a DIY job, you’ll need to purchase a new timing belt, tensioner and idler pulleys, specialized tools, and maybe a water pump. Individual parts will cost between $150 and $500, while a kit will be $100 to $350.

Professional replacement services generally run between $400 and $1,100 for parts and labor, with some high-end or complex engines costing even more. If your faulty timing belt has caused more damage to other parts, the price can go up to $2,000 or more.

While doing it yourself can save money, it may take longer and can be a complex job, with the potential for costly mistakes. Weigh your budget and time options before committing to a DIY project.

Step-by-Step Guide on How to Replace a Timing Belt

Replacing a timing belt requires patience and precision. Before you do anything, go through your tune-up checklist and note any engine repair work you may need to do. You’ll be opening up your engine and replacing a major component, so you might as well replace or repair other parts. Here’s a general guide on how to replace a timing chain or belt, but specific steps may vary depending on your vehicle’s make and model.

1. Preparation

Start by parking your car on a level surface and engaging the parking brake. Disconnect the negative battery terminal to prevent electrical shorts. Raise the front of the vehicle using jack stands, ensuring it’s stable and secure.

2. Accessing the Timing Belt

Remove components blocking access to the timing belt cover. These may include the radiator fan and shroud, power steering pump, water pump pulley, and crankshaft pulley or harmonic balancer.

As you remove these pieces, keep track of all bolts and their locations. Using labeled bags or pegboards can help ensure everything goes back in the right place.

3. Removing the Old Timing Belt

Once you’ve exposed the timing belt, align the timing marks on the crankshaft and camshaft pulleys. These marks ensure the engine is in the correct position for belt removal and installation.

Loosen the tensioner pulley to release tension on the belt. Carefully remove the old timing belt, taking note of its routing.

4. Installing the New Timing Belt

Before installing the new belt, it’s a good time to replace the water pump if the timing belt drives it. Many mechanics recommend doing this as preventive maintenance. You should also check and possibly replace your engine air filter, especially if you have a timing chain. A clean air filter is vital to proper timing belt and engine performance.

After replacing your water pump and engine air filter, carefully route the new timing belt according to your vehicle’s specific pattern. Ensure all timing marks are still aligned. Tension the belt according to manufacturer specifications using the tensioner pulley.

5. Reassembling Components

Once your new belt is in place, begin reassembling all removed components in the reverse order of removal. While you have access to this area of your engine, it might be a good time to check or replace your spark plugs before putting everything in place. Double-check all connections and ensure everything is properly placed and tightened to the correct torque specifications.

6. Testing Your Work

After reassembly, reconnect the battery. Start the engine and listen for unusual noises.

Let the engine run for a few minutes, then turn it off and check for leaks. If everything seems in order, take the car for a short test drive, paying attention to unusual sounds or performance issues.

Keeping Your Engine in Sync

Replacing a timing belt is critical to your engine’s health and performance. While it may seem daunting, understanding the process and recognizing the signs of wear can help you keep your car running smoothly for years.